Water heater performance improvment made so easy !

How to Improve the performance of a water heater … without a water heater!

Our customer is developing a new range of thermodynamic water heaters. They needed to find the best parameters for the energy efficiency of this future range before producing the first prototype.

The challenges:

– Provide reliable answers in less than 2 months

– Achieving the best performance with contradictory indicators such as efficiency and the V40

– Removing uncertainties linked to empirical hypotheses or beliefs

– Provide maximum comfort (V40)

– Integrate the use of components already chosen upstream.

The result:

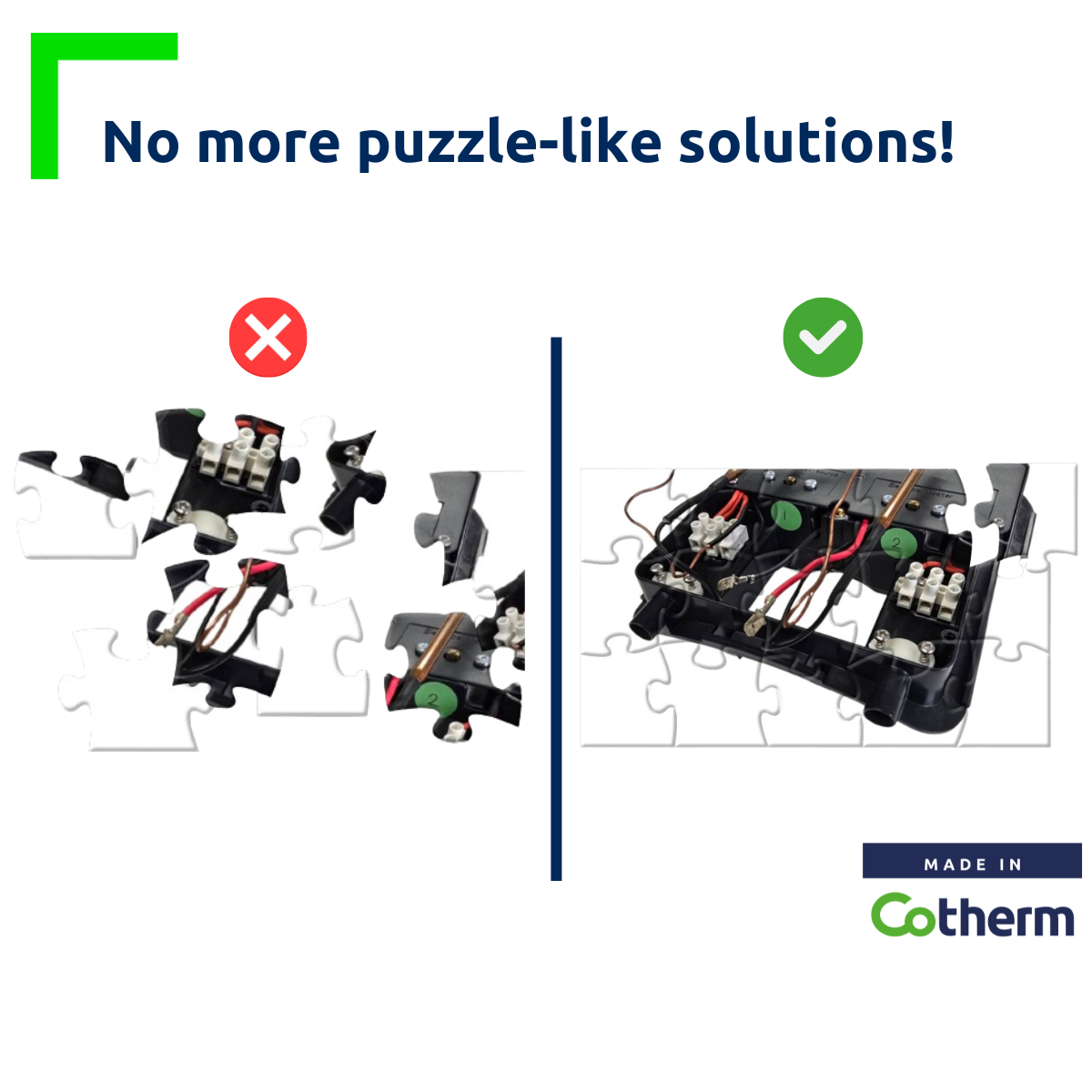

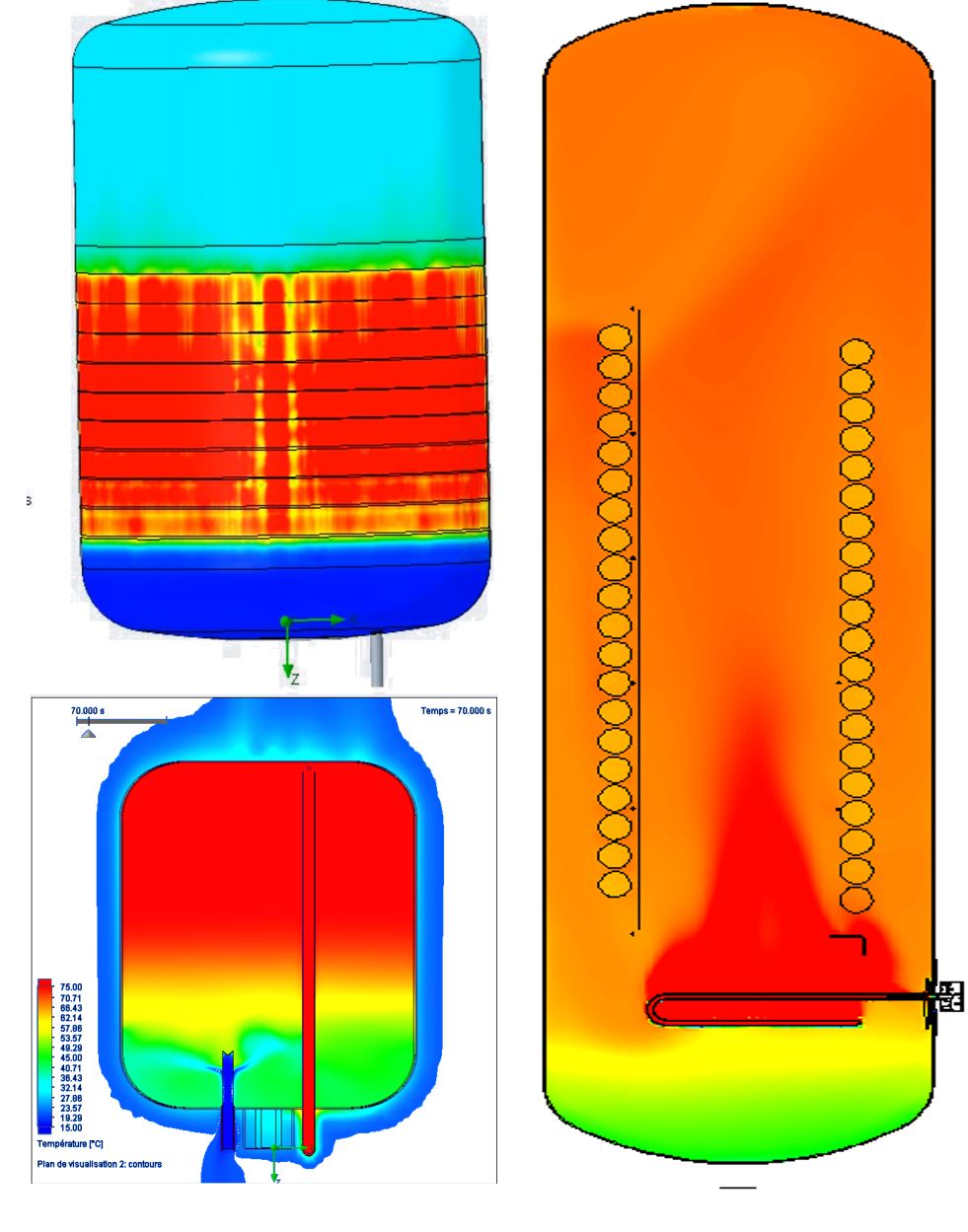

Thanks to the CFD simulation carried out by COTHERM of the tank, exchanger-condenser assembly, and constituent equipment such as probes, resistance and water inlet/outlet connections, we were able to define in less than 2 months

– A water inlet adapted to the tank to optimise the stratification phenomenon

– Temperature measurement positions and points adapted to the tank and exchanger

And obtained performance results that exceeded the initial objective.

Key figures:

– A 200 L thermodynamic water heater

– A solution defined in 2 months

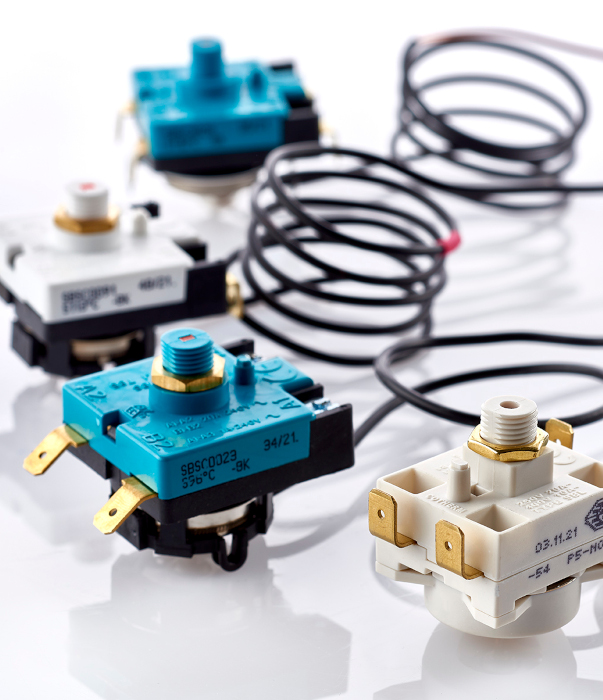

– A target market of several thousand Cotherm iHPW 3000 controlers and sensor, safety and heating elements.

What is CFD simulation?

CFD stands for Computational Fluid Dynamics. This simulation method enables us to understand the overall behaviour of a water heater through the interaction of fluids (liquids and gases), as well as other parameters such as heat exchange and chemical reactions.

CFD enables our customers to limit their investment in terms of both time and materials:

– The time required for testing is halved

CFD, another Cotherm know-how

After two years’ work and using our test database of over 1,000 electric and thermodynamic water heaters, COTHERM has established a numerical database of different water heater models. Thanks to our digital reference base, we are able to check or define the technical choices relating to static losses, water inlet/outlet dynamics combined with heating and comfort (V40 ) on different configurations in record time, without having to commit to a product prototype or even a component, which can take several weeks or months.

he Cotherm process :

Beforehand, tests on equivalent products were carried out in the laboratory. This data enabled us to calibrate our CFD simulation tool using the same parameters.

Phase 1: Request for a service from our customer for a range currently being created. Definition of the objectives, characteristics of the project, establishment of the schedule and budget.

Phase 2: Our design office teams discuss the project with the customer’s technical teams to precisely define the project constraints and the result to be achieved.

Phase 3: Start of CFD simulations.

An initial study enabled us to propose an optimised design for the cold water inlet. This design saved almost twenty litres of hot water equivalent at 40°C compared with the original concept.

For this project, 4 different probe lengths and 3 positions will be tested. The aim was to identify the position of the sensor that would give the best V40 while guaranteeing the target efficiency.

3 simulations were carried out to obtain the best result.

Phase 4: One of the scenarios was validated, tested under real conditions in our laboratories, and finally deployed on the range of thermodynamic water heaters.

Product range selection

Contrôler, Sécuriser et Chauffer