Compact Water heater

Our use case: High power compact water heater

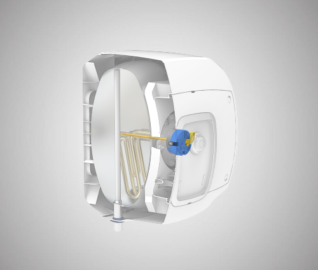

For a project involving the design of a new wall-mounted water heater, our client was constrained with a compact solution, with a shallow form factor (reduced thickness), high power for maximum hot water volume and an entry-level market target requiring the use of low-cost technology while meeting stringent safety standards.

What is a compact water heater?

Are classified in the category of small water heaters or compact water heaters, storage water heaters intended to supply a single point of use such as a washbasin / sink rather intended for hand washing or a bathroom with shower.

These products have a capacity ranging from 5 to 30 liters and are classified according to European profiles in categories XXS to XS.

It is necessary to distinguish the compact water heater from the instantaneous water heater which heats the water instantly with a high power resistance, only possible in regions with compatible electric meters.

What is the challenge of this type of application?

The first challenge of this type of application is to provide a level of comfort in adequacy with the needs which are measured in quantity of hot water equivalent to 40°C (V40). The performance obtained is a result of the size of the tank, the heating power of the electric resistance, the positioning of the resistance in the tank and the form factor of the water heater, often linked to its installation location (over the sink, under the sink, under the ceiling). The second challenge is to ensure the safety of the product. Due to the size of the reduced tanks, the resistances used tend to have higher powers than a classic water heater of 50 L and more. We find ourselves with power ratings ranging from 1.5k to 2.5kW for water volumes of 5L to 30L. In these configurations, the complete heating time can be less than 15 minutes and a bad dimensioning of the regulation or of the security can transform the water heater into a mini-bomb, the high temperatures generating strong pressures in the tank. The third challenge is, depending on the region, an optimal target energy efficiency which depends for a lot on the regulation and the resistance. In order to ensure conformity with the market, the results obtained in the laboratory on prototypes must be reproducible in large-scale production and during control by certified laboratories. Our use case: For a project involving the design of a new wall-mounted water heater, our client was constrained with a compact solution, with a shallow form factor (reduced thickness), high power for maximum hot water volume and an entry-level market target requiring the use of low-cost technology while meeting stringent safety standards.

The process:

We applied the 4-phase coaching project process (link to coaching) The project started with an exchange to establish the product specifications. Thanks to Cotherm’s experience with this type of product and the knowledge database established through laboratory and field measurements, we quickly converged on technical specifications, a target price and a budget for the application device compatible with the target market. Following this exchange, the design phase begins. We prepare prototype samples of thermostat and resistor and our customer prepares a sample tank according to the recommendations. Generally between 2 and 3 samples of water heaters may be necessary in the case of studying different variants. This phase took place in 5 weeks, corresponding to the time needed to produce validated plans and prototype tanks, with each party having samples for its tests. This is followed by the solution qualification phase. Cotherm is equipped with test laboratories configured according to the various applicable standards. Measurements are performed according to IEC60379 (performance), IEC 60335-1 and IEC 60335-2-21 for safety and SASO 2884, EU 2013/812 and 814 energy performance regulations according to the EN 50 440 measurement method. Taking into account the market objective, the chosen solution is a thermostat type control with a triangular resistor shape and a front panel mounting offering the user the option to choose his temperature level. This solution offers the possibility to opt for an EcoFlex option, for a better energy class for areas requiring high energy performance, without changing the structure of the water heater. The deployment went smoothly, with certification of the solution by an independent laboratory without any surprises and a quick production start-up of a few weeks after validation of the final plans.

Conclusion:

We were able to respond with a solution combining thermostat, safety and resistance for an economical compact water heater that can meet the traditional markets of electric water heaters, with a high level of comfort but open the possibility of a more efficient version thanks to the EcoFlex technology for the European markets.

Key figures:

Project duration: 9 months

3 prototypes

17 tests carried out

Quantity: several tens of thousands per year

Efficiency control: Every year on serial products

Solution: 2.5 kW copper resistor -triangle shape / short rod Thermostat with EcoFlex technology sensor

Applicable solutions

Here are the ranges selected for this use case