Your new heat pump offer within a few months!

How can you ensure that your new range of heat pump water heaters is introduced in just a few months?

This was the challenge faced by our customer, who wanted to rapidly deploy a new range of heat pump water heaters, with the following requirements:

- A proven, customisable solution, making it easy to bring to market.

- A packaged solution comprising the electronics, the cloud connectivity service and the application for IoS or Android smartphones.

- A solution that delivers the performance that makes the product eligible for state subsidies, essential for commercial success.

- A controller that is compatible with photovoltaic-type self-consumption installations or current and/or future smart grid services.

- A support service for a reliable and secure connected solution.

- Support for field tests to validate the solution.

- A branded application that is reliable and scalable with the rapid development of smartphone technologies.

- An easy-to-use solution.

Key figures:

- Availability of products for field trials in less than 3 months. 12 months of field trials for marketing 6 months later.

- 2 tank capacities: 200L and 285L

- Several thousand units sold per year

What is a heat pump water heater?

A thermodynamic water heater is an appliance that incorporates a heat pump as well as an electric heating elements. This heat pump recovers the calories naturally present in the air to heat domestic hot water. The solution is known to be particularly economical: the resource used (air) is in fact free and infinitely renewable. This type of equipment can achieve energy savings of up to 75% compared with a conventional electric water heater. As heat recovery is only possible in compatible temperature ranges, heat pump water-heaters are generally fitted with an electric heating element to provide comfort in extreme conditions.

What are the challenges for regulation in this application?

This type of project poses a number of different challenges:

- Ensure the reliability of the heat pump.

- Secure the equipment.

- Choose the best settings to optimise energy savings.

- Offer the level of comfort requested by the user.

- Adapt to the regulatory requirements specific to each region.

- Perform according to the type of installation targeted: room air, outside air, extract air.

- Be able to adapt to the flexibility required by electricity networks.

- Be synchronous with free energy sources such as photovoltaic panels.

- Enable users to benefit from preferential tariffs when these are available.

- Be able to integrate a multi-source heat system (heating element, boiler, etc.).

- Be certified by an independent laboratory for safety and reliability, making it easier for the customer to certify the water heater.

The Cotherm process:

The customer immediately saw the value of an off-the-shelf solution offered by Cotherm, which enabled them to carry out a rapid field test with users, to quickly validate the solution and identify the technical points to be customised.

Phase 1: Strategy

It starts with a discussion of our customer’s strategy: What is the target market segment? What are the essential functions, the applicable regulatory requirements, the annual quantities expected and its industrial and R&D capacities? Based on these elements, Cotherm proposes the most appropriate solution, which may be based on one of our platforms, or on a customised product design using our technological building blocks.

In the case of our customer, it was the iHPW 1000, a competitive and available product, that was best suited to the specifications. It’s a one-piece product that includes the control system and the user interface, and brings together 100% of the functions that are relevant and essential to the operation of a heat pump water-heater. The physical interface is simple to use, with the main functions accessible directly on the water heater, such as choosing the comfort level or boosting if necessary, while the more advanced functions for occasional use are available via the smartphone APP supplied with the controller.

Installation on the water heater is very simple, thanks to front-installation through a simple calibrated opening, which can be achieved with very little investment.

Phase 2: Testing

As the product was available, it was very easy to deploy a full-scale test. So 10 heat pump water-heaters were fitted with the control system and deployed in the field, with 2 reference products in the laboratory and 8 products in the homes of company employees. We covered a full season (one year) in order to test the regulation as well as the other components making up the solution, such as the compressor, the evaporator and the defrosting solutions. The heat pump water-heaters deployed were all equipped with the iHPW 1021 solution, which includes connected remote control and consumption monitoring functions. Following this initial small-scale test, more than 100 water heaters were subsequently deployed to enhance the test results.

Phase 3: Customisation

Field trials have enabled us to identify adjustments and define a set of parameters to adapt the solution to the market. The iHPW 1000 is equipped with modular, parameterisable software. Nearly 100 accessible parameters can be adjusted by our customer, such as maximum heat pump regulation values, climatic operating limit values or more technical parameters, affecting defrost modes or the various hysteresis and time delays. The result is a set of specific parameters that will be used during production.

The user interface was also customised. In the case of our customer, we removed access to certain functions such as adjusting the temperature on the product, which is fixed and determined by our customer. This has been reduced to 4 functions accessible directly on the UI, without the use of the application, which are Frost Protection, Eco, Auto and Boost.

The application itself was customised with the customer’s colours and branding, and made available on the download stores by Cotherm.

Phase 4: Production and sales

Following field trials, Cotherm supplies the complete solution, which includes :

- Customised iHPW 1000 electronic controls

- Provisioning of the iHPW 1000 on the customised cloud space dedicated to our customer.

- IOS and Android application, customised and downloadable from the stores.

- Cloud and application maintenance

The solution is currently being deployed with 2 water heater capacities: 200L and 285L.

To sum up:

The heat pump water-heaters could be marketed with very little development work, thanks to a tried and tested controller with functions developed by Cotherm in line with market expectations. The field phase, which was essential, enabled the product to be customised and parameterised as much as possible for smooth industrialisation and marketing.

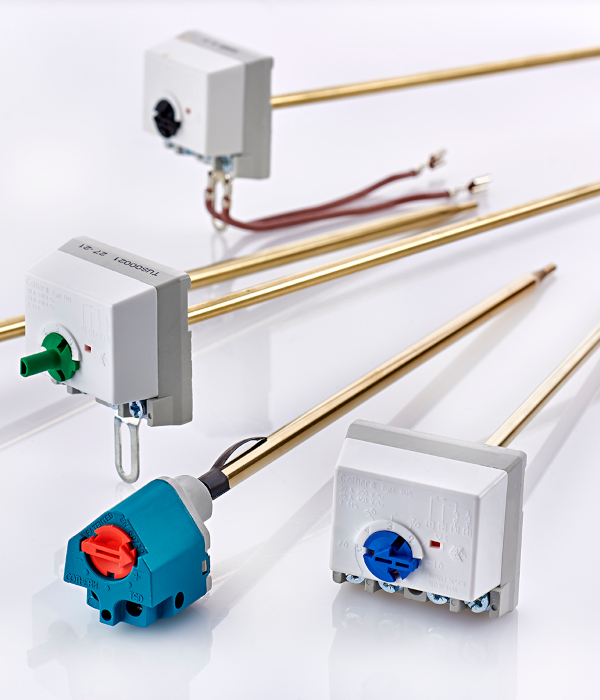

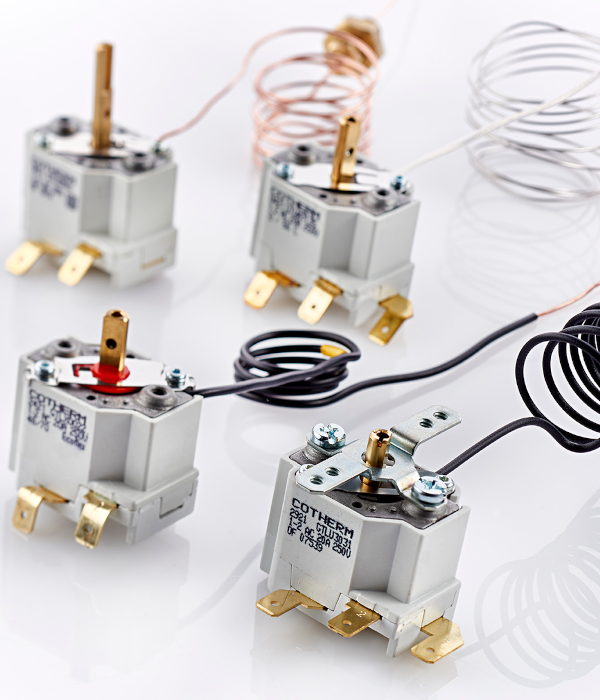

Product range

Control, Secure and Heat